Rubber Expansion Joint

- Keyser Rubber Expansion Joints

- Product Description

- Construction Details

- Basic Spool Type Expansion Joints

- Single Sphere Connectors With Floating Flange

- Twin Sphere Connectors With Floating Flange

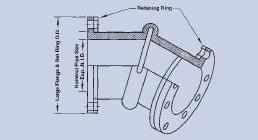

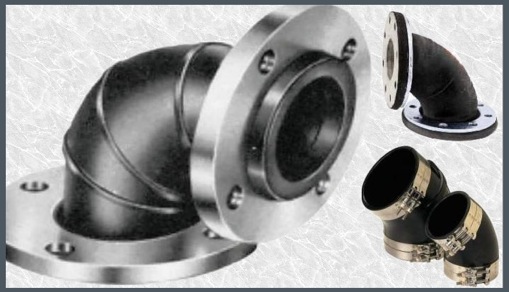

- Elbow Connectors

- More Rubber Expansion Joints Products

KEYSER Rubber expansion joints are used by professionals in industries such as plant engineers, consulting engineers, pressure vessel designers and mechanical contractors. Rubber expansion joints are installed for the purpose of protecting piping from expansion and contraction, as well as ensuring maximum efficient and economical on-stream operations. Rubber expansion joint is a specifically engineered and designed section of the pipes that is flanged. They are able to be inserted within a rigid piping system to achieve the following:

- Absorb movements

- Relieving of system strain due to various reasons such as thermal change, load stress, pumping surges, wear or settling

- Reducing mechanical noise

- Compensation for any misalignment that occurred

- Eliminating electrolysis between dissimilar metals

Rubber expansion joints, designed by engineers and fabricated by skilled craftsmen, are used in all systems conveying fluids under pressure and or vacuum at various temperatures.

Product Description

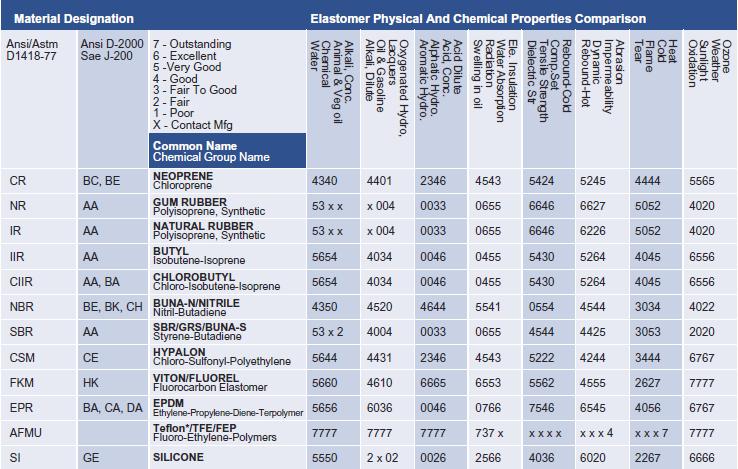

Definition:

A rubber expansion joint is a flexible connector fabricated using natural or synthetic elastomers and fabrics. At times, metallic reinforcements are used when necessary to provide stress relief in piping systems due to thermal and mechanical vibration and/or movements. Flexibility and concurrent movements in either single or multiple arch type construction, isolation of vibration and noise resistance to abrasion and chemical erosion are some of the key features.

Functions:

By incorporating rubber expansion joints during the piping system design, engineers are able to remove or significantly reduce any likelihood of problems such as vibration, shock, noise, stresses, corrosion and abrasion.

Reduced Vibration:

Vibration caused by equipment are isolated or significantly reduced with the installation of Rubber expansion joints. The following example is based on true tests conducted by a independent, nationally recognized testing laboratory. The use of reciprocating pumps and compressor generate greater unbalanced forces than centrifugal equipment. By using rubber pipe and expansion joints, any undesirable disturbances including harmonic overtones and vibrations caused by centrifugal pump and fan blade frequency are greatly reduced or removed. Thus, with this illustration, rubber expansion joints reduce transmission of vibration and protect equipment from the adverse effects of vibration.

Dampening of Sound Transmission:

Imbalance in motive equipment generates undesirable noises transmitted to occupied areas due to reasons such as going on stream, normal wear, corrosion, abrasion and erosion. The use of rubber expansion joint dampens likelihood of transmission of such sound because of the steel-rubber expansion joints, compared with their metallic counterparts

Compensate Lateral, Torsional and Angular Movements.

Due to wear and load stresses, equipments such as pumps, compressors, fans and piping equipment tends to move out of alignment. The use of rubber expansion joints compensate for any lateral, torsional and angular movements thus greatly reduces or removes any damage and undue downtime of plant operation.

Compensate Axial Movements

The use of rubber expansion joints in strategic locations will reduce any expansion and contraction movements due to thermal changes or hydraulic surge effects. They act as helix springs, compensating for axial movements.

Advantages

The industry has allied itself with designers, architects, contractors and erectors in designing and fabricating rubber expansion joints under rigid standards to meet present-day operating conditions. By keeping abreast of the technological advances in rubber compounding and synthetic fabrics, the industry allies itself with different rubber expansion joints having advantages not available in other materials.

Minimal Face to face Dimensions

When compared with costly expansion bends or loops, there is minimal face-to-face dimensions in rubber expansion joints. The relative cost of the pipe itself may be less than rubber expansion joints. Taking into account plant space, installation labour, supports and pressure drops, the end total cost could be significantly higher.

Light-weight

Rubber expansion joints are light thus there is no special equipment required to fit them into position, and this lowers installation and labour costs.

Reduced Fatigue Factor

The inherent characteristics of natural and synthetic elastomers are not subjected to fatigue breakdown or embrittlement. This prevents any electrolytic action because of the steel-rubber interface of joints and flanges.

Reduced Heat Loss

Rubber expansion joints significantly reduce heat loss and also reducing frequency of maintenance.

Corrosion & Erosion Resistant

There is a wide range and variety of natural synthetic and special purpose elastomers and fabrics available. Materials are treated and combined in order to meet a wide range practical pressure-temperature operating conditions and other forms of corrosive attack, abrasion and erosion. There are standard and special sizes of rubber expansion joints which are available with TFE/FEP liners, fabricated to the configurations of the joint body, as added insurance against corrosive attack. Teflon possess unusual and unique characteristics of thermal stability, non-sticking surface, extremely low co-efficient of friction and resistance to most corrosive fluids and forms of chemical attack.

No Gasket required

The use of gasket are unnecessary as the elastomeric expansion joints are supplied with flanges of vulcanized rubber and fabric integrated with the tube. The sealing surfaces of the expansion joint equalize uneven surfaces of the pipe flange to provide a fluid and gas-tight seal.

Excellent Noise & Shock resistance

The elastomeric composition of the elastomeric expansion joints acts as a dampener that absorbs the noise and vibration, thus greatly reduces any noise transmission in piping systems. They also provide good resistance against

shock stress from excessive hydraulic surge, water hammer or pump cavitation.

Construction Details

Cover:

The exterior surface of the joint is formed from natural or synthetic rubber, depending on service requirements. Its primary function is to protect the carcass from external abuse or damage. A protective costing may be applied to the exterior of the joint for additional protection. Similarly, special polymers can be added to resist chemicals, oils, sunlight, acid fumes and ozone.

Tube:

A protective leak-proof lining made up of synthetic or natural rubber as the service dictates. This is a seamless tube that extends through the bore to the outside edges of the flanges. Its purpose is to eliminate the possibility of the materials being handled penetrating the carcass and weakening the fabric. These tubes can be designed to cover service conditions for chemical petroleum, sewage, gaseous and abrasive materials.

Metal Reinforcements:

Wire or solid steel rings are embedded in the carcass are used as strengthening members of the joint. At times, this raises the rated working pressure and can supply rigidity to the joint for vacuum service.

Fabric Reinforcements:

The carcass fabric reinforcement is the flexible and supporting member between the tube and cover. Standard constructions usually utilize high quality synthetic fabric. At times, natural fabrics are used at some pressures and temperatures. All fabric plies added with rubber or synthetic compounds to permit flexibility between the plies.

Basic Spool Type Expansion Joints

Single Arch Type

¥ Fabric & rubber construction

¥ Reinforced with metal/wire rings

¥ Full face flanges integral with joint body

¥ Flanges drilled to companion bolt pattern

¥ Gaskets not required

Multiple Arch Type

¥ Allows greater movement compared to single arch type joints

¥ The minimum joint length is dependent on the number of arches

¥ For maximum stability, 4 arches is recommended

Offset Type

¥ Can be customised to specific requirements

¥ Initial misalignment and non-parallelism of piping axis will be compensated.

Sleeve Type

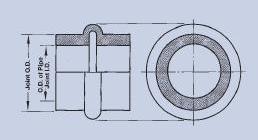

¥ This type has the same design as the single arch type. The only difference is that the sleeve ends have an I.D. equal to the pipe O.D.

¥ Clamps are used to secure the ends

¥ Only recommended for low pressure service only

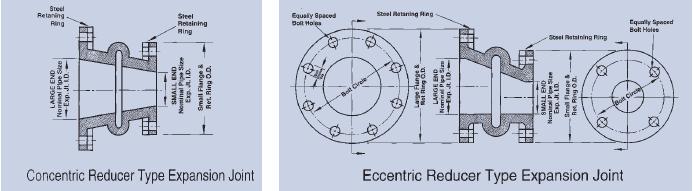

Taper Reducer Type

¥ Able to connect different piping

¥ May be customised according to specific requirements.

¥ Tapers of 15 or less are recommended.

¥ Pressure ratings are based on larger I.D.

¥ Available with and without arches

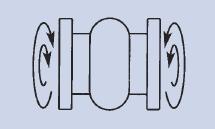

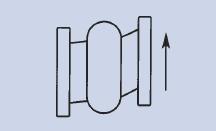

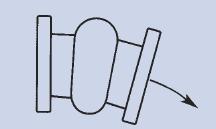

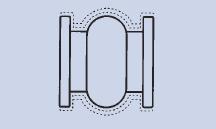

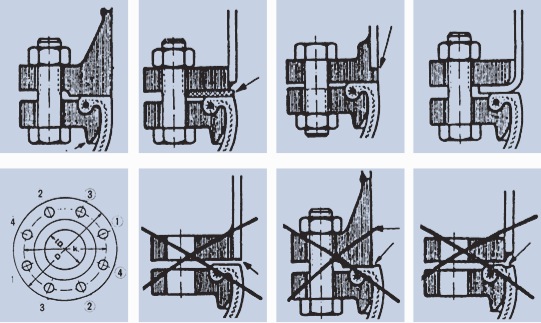

Movements In Industrial Piping

Axial Compression

¥ Longitudinal movement shortens face to face dimension along axis of expansion joint/flexible coupling

¥ Pipe flanges remain perpendicular to axis

Axial Extension

¥ Longitudinal movement shortens face to face dimension along axis of expansion joint/flexible coupling

¥ Pipe flanges remain perpendicular to axis

Torsional Movement

¥ Rotation of one flange with stationary counterpart

¥ Simultaneous rotation of both flanges in opposing motion

Lateral/Transverse Movement

¥ Offset movement of one both pipe flanges

¥ Both flanges remain parallel to each other while forming angle to axis of joint

Angular Movement

¥ Deflection/rotation of one or both flanges

¥ Angle with axis of expansion joint/flexible coupling is formed Vibration

¥ By definition, this is the oscillating movement around axis of expansion

Joint/Flexible coupling

¥ Pipe flanges remain parallel with each other

¥ Flanges remain perpendicular to axis

¥ Mechanical vibration in steel piping system reduced with installation of pipe connection of pipe connectors/expansion joints

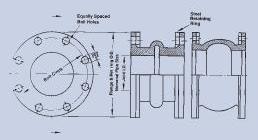

Single Sphere Connectors With Floating Flange

May be used both for Suction and Delivery

Because of the excellent moulding technique combined with tough chemical fibers, it may be used at a bursting pressure of over 850 p.s.i. and within a normal internal pressure of 225 p.s.i. Since it can satisfactorily withstand the force for creating a vacuum, it may be used on both the delivery and the suction sides. Its carcass is made of special spherical type, it will not come in contact with the connecting bolt head even if it expands, this connector may be used with a sense of security even when subjected to high pressures.

Easy Installation on Piping

Since its carcass is soft and can be readily deformed, pipe connections can be quickly and readily completed despite some misalignment.

Excellent Ability to isolate Sound and Vibration

The highly soft carcass isolates vibration and solid sound in all directions and prevents the production of noise.

OTHER ADVANTAGES AND EFFECTS

- Need neither gasket nor packing.

- Since the flange is sort of loose fit type, it can be installed on pipes without difficulty.

- Since it absorbs the elongation and contraction of pipes caused by variations in temperature, it prevents the piping system and equipment from breaking down.

- It absorbs the pulsation of water and prevents water hammering to some extent.

- When pipes made of different engineering materials are connected with this connector, it prevents them from developing electrolytic corrosion.

TYPICAL APPLICATIONS:

- Pressure piping systems for water and warm water used in building equipment and general industrial plants, etc.

- Pump lines and turbine lines used for power generation plants, industrial machinery, universal pump blowers, etc.

- Feed-water and drainage lines for waterworks, sewerage, sanitary piping systems, etc.

- Oil lines for industrial plants, shipbuilding yard, etc.

- Loading and unloading lines to and from ships for harbor facilities, etc.

Others: This connector has a wide range of applications in waste disposal plants, mines, chemical plants, etc.

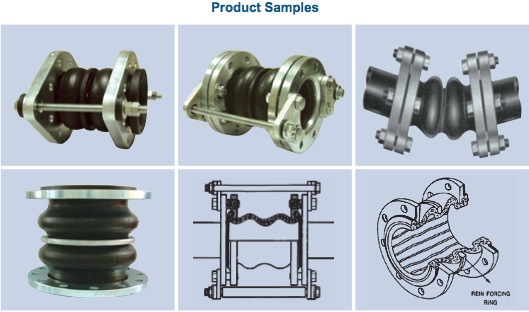

Product Samples

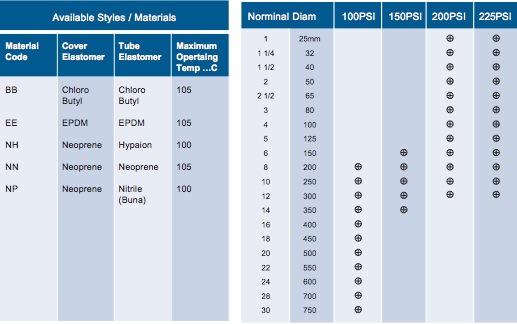

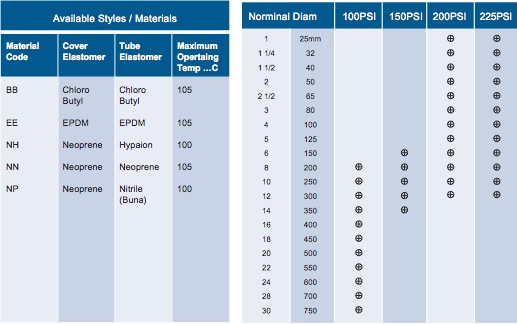

Available Styles / Materials

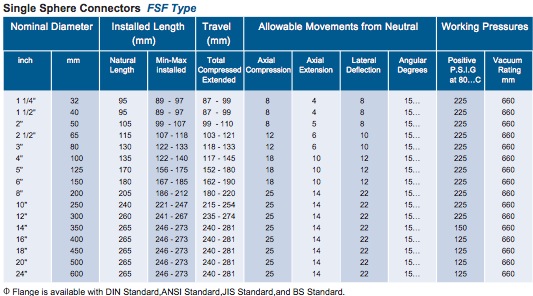

Single Sphere Connectors (FSF Type)

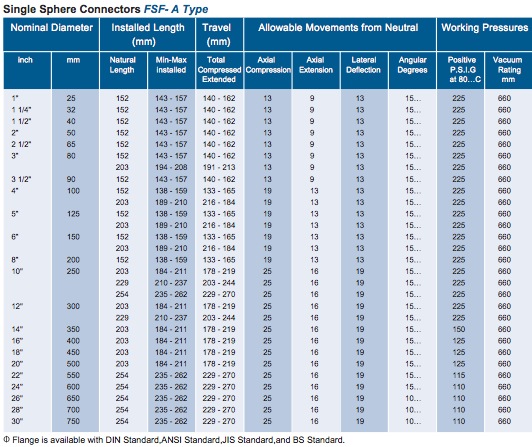

Single Sphere Connectors (FSF- A Type)

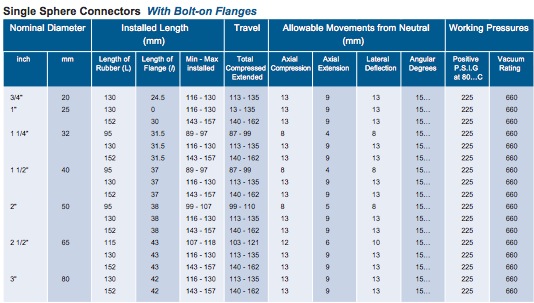

Single Sphere Connectors (With Bolt-on Flanges)

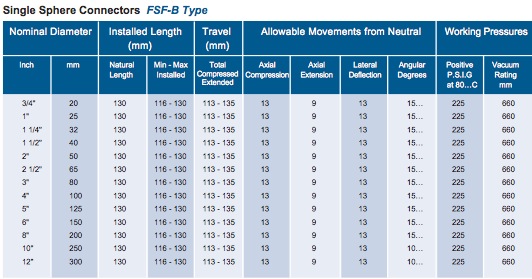

Single Sphere Connectors (FSF-B Type)

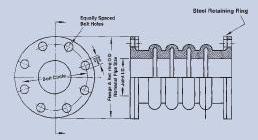

Twin Sphere Connectors With Floating Flange

May be used both for Suction and Delivery

Because of the excellent moulding technique combined with tough chemical fibers it may be used at a bursting pressure of over 850 p.s.i. and within a normal internal pressure of withstand the force for creating a vacuum it may be used on both the carcass is of will not come in contact with the connecting bolt head even if it expands, this connector may be used with a sense of security even when subjected to high pressures.

Easy Installation on Piping

Since its carcass is soft and can be readily deformed, pipe connections can be quickly and readily completed despite some misalignment.

Excellent Ability to isolate Sound and Vibration

The highly soft carcass isolates vibration and solid sound in all directions and prevents the production of noise.

OTHER ADVANTAGES AND EFFECTS

- Need neither gasket nor packing.

- Since the flange is sort of loose fit type, it can be installed on pipes without difficulty.

- Since it absorbs the elongation and contraction of pipes caused by variations in temperature, it prevents the piping system and equipment from breaking down.

- It absorbs the pulsation of water and prevents water hammering to some extent.

- When pipes made of different engineering materials are connected with this connector, it prevents them from developing electrolytic corrosion.

TYPICAL APPLICATIONS:

- Pressure piping systems for water and warm water used in building equipment and general industrial plants, etc.

- Pump lines and turbine lines used for power generation plants, industrial machinery, universal pump blowers, etc.

- Feed-water and drainage lines for waterworks, sewerage, sanitary piping systems, etc.

- Oil lines for industrial plants, shipbuilding yard, etc.

- Loading and unloading lines to and from ships for harbor facilities, etc.

Others: This connector has a wide range of applications in waste disposal plants, mines, chemical plants, etc.

Product Samples

Available Styles / Materials

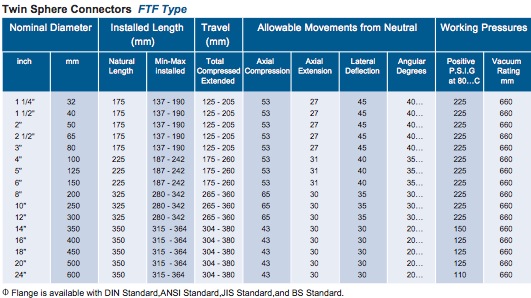

Twin Sphere (FTF Type)

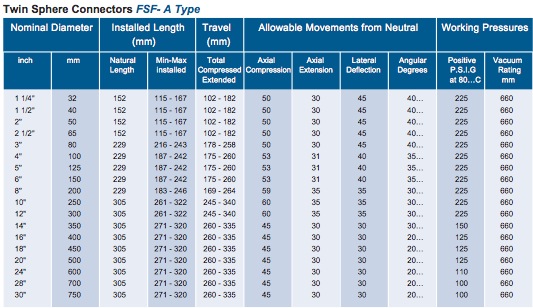

Twin Sphere (FSF- A Type)

Twin Sphere (FTF- B Type)

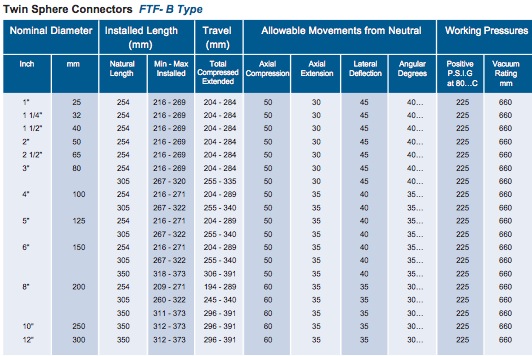

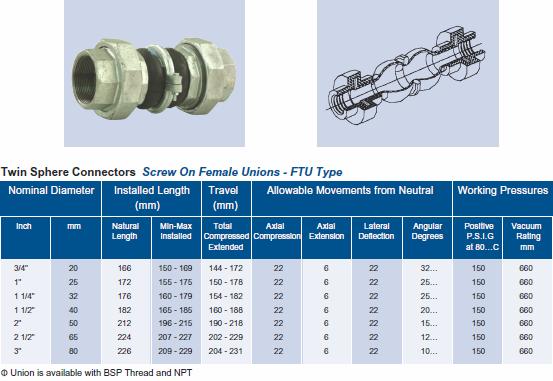

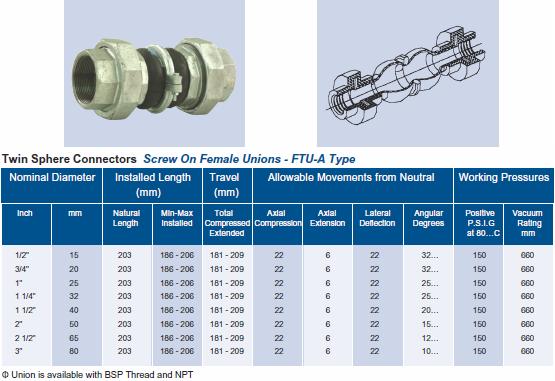

Twin Sphere Connectors Screw On Female Unions – FTU Type

Twin Sphere Connectors Screw On Female Unions – FTU-A Type

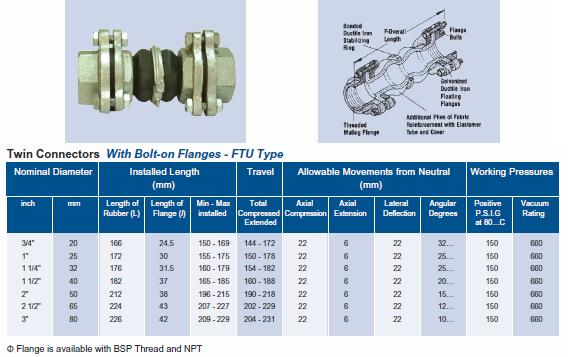

Twin Sphere Connectors With Bolt-on Flanges – FTU Type

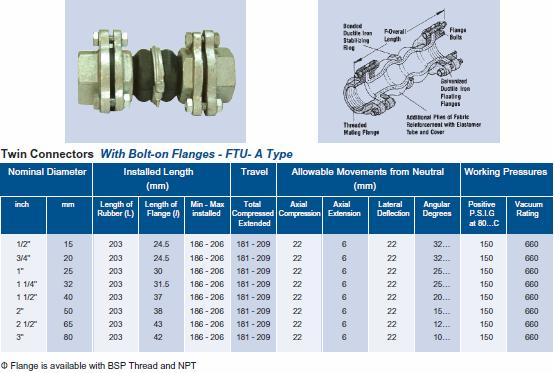

Twin Sphere Connectors With Bolt-on Flanges – FTU- A Type

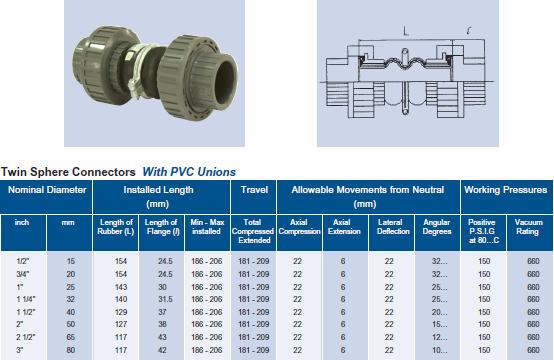

Twin Sphere Connectors With PVC Unions

Elbow Connectors

The cost of Keyser rubber bellow is comparable to the steel it replaces and certainly less than the cost of a steel elbow plus a straight line connector. When Keyser rubber elbows are used, the pump foundation need no longer be made large enough to support the base elbows and this reduces the cost of the foundation. Because the piping must be properly supported from above rather than rest on the pump foundation, there is better chance that the pump foundation can operate properly. The reduced foundation weight is often important in lightweight equipment rooms as well.

The cost of Keyser rubber bellow is comparable to the steel it replaces and certainly less than the cost of a steel elbow plus a straight line connector. When Keyser rubber elbows are used, the pump foundation need no longer be made large enough to support the base elbows and this reduces the cost of the foundation. Because the piping must be properly supported from above rather than rest on the pump foundation, there is better chance that the pump foundation can operate properly. The reduced foundation weight is often important in lightweight equipment rooms as well.

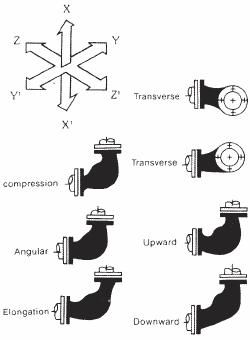

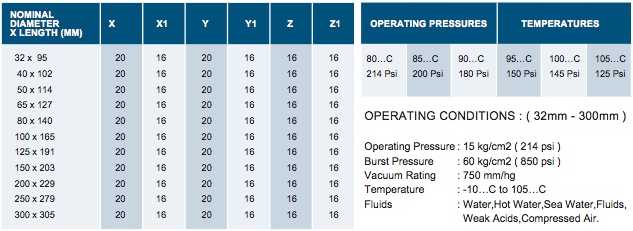

Movement

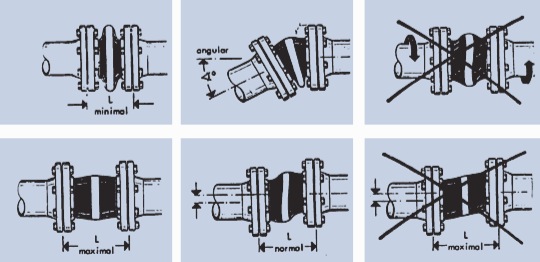

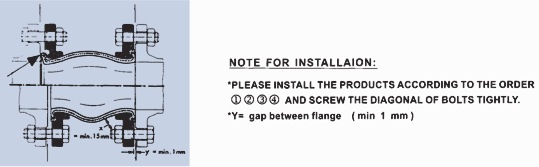

Installation Instructions

More Rubber Expansion Joints Products

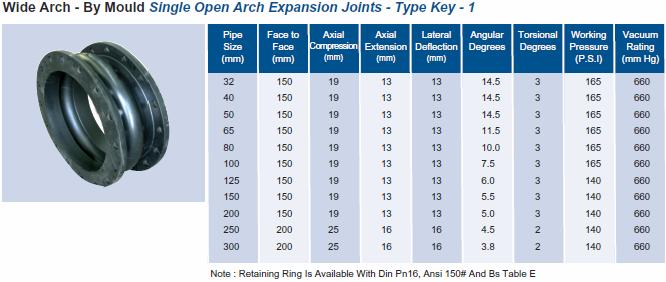

Wide Arch – By Mould Single Open Arch Expansion Joints – Type Key – 1

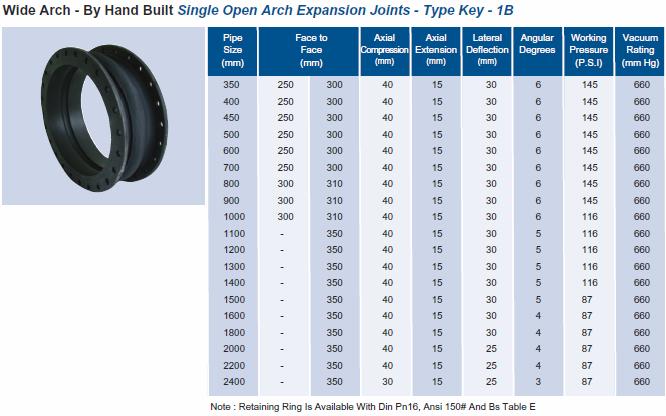

Wide Arch – By Hand Built Single Open Arch Expansion Joints – Type Key – 1B

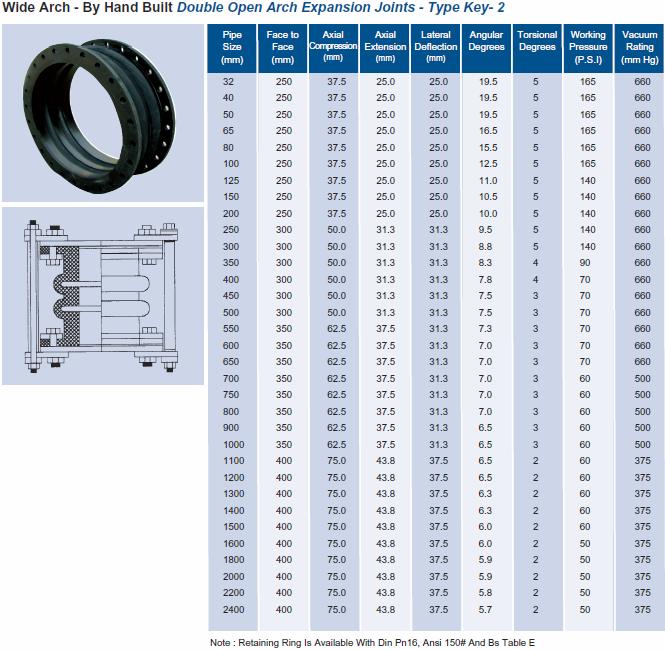

Wide Arch – By Hand Built Double Open Arch Expansion Joints – Type Key- 2

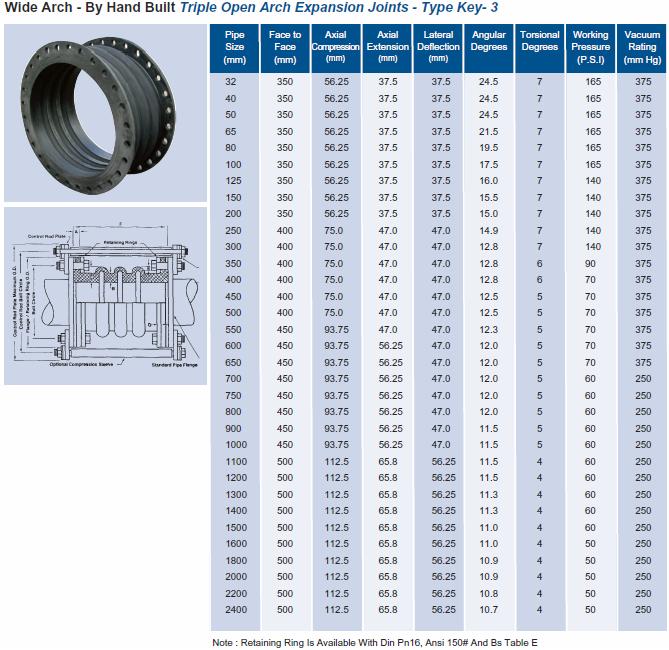

Wide Arch – By Hand Built Triple Open Arch Expansion Joints – Type Key- 3

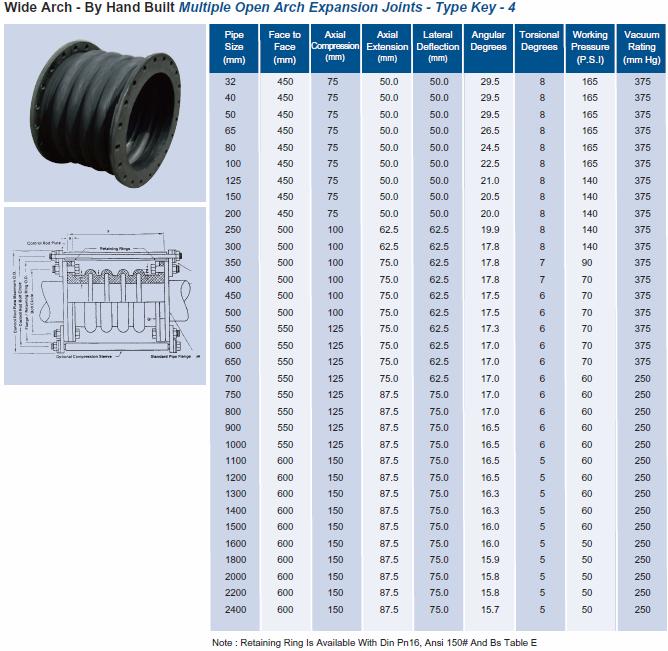

Wide Arch – By Hand Built Multiple Open Arch Expansion Joints – Type Key – 4

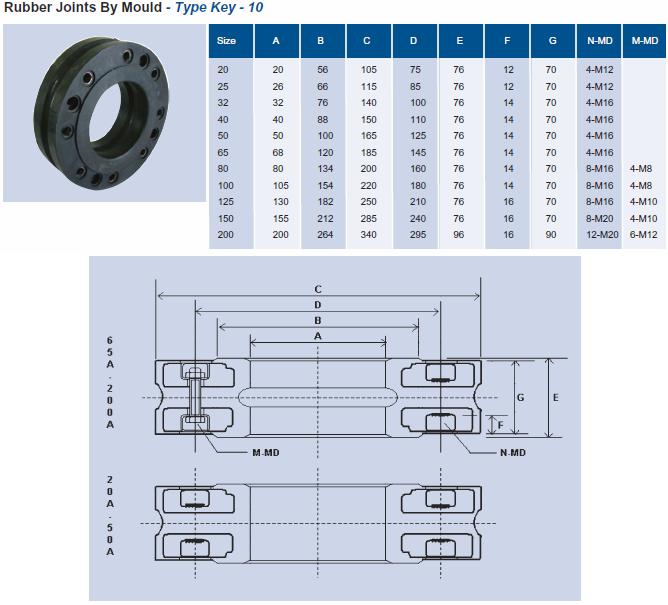

Rubber Joints By Mould – Type Key – 10

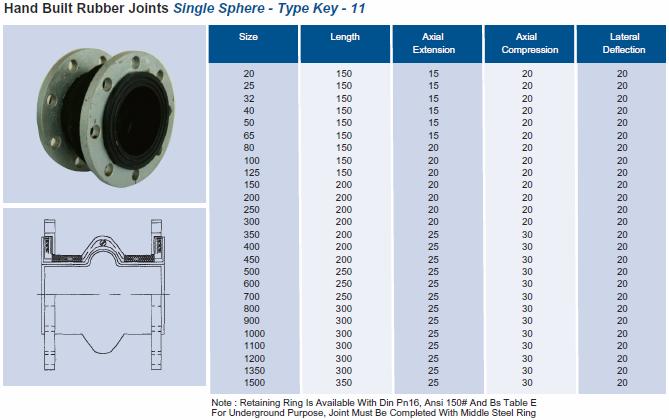

Hand Built Rubber Joints Single Sphere – Type Key – 11

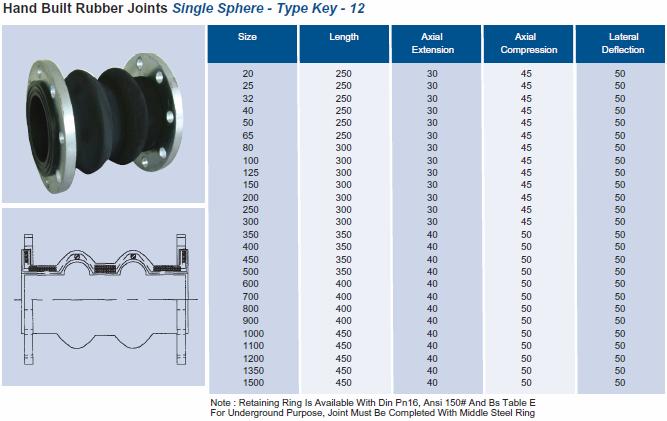

Hand Built Rubber Joints Single Sphere – Type Key – 12

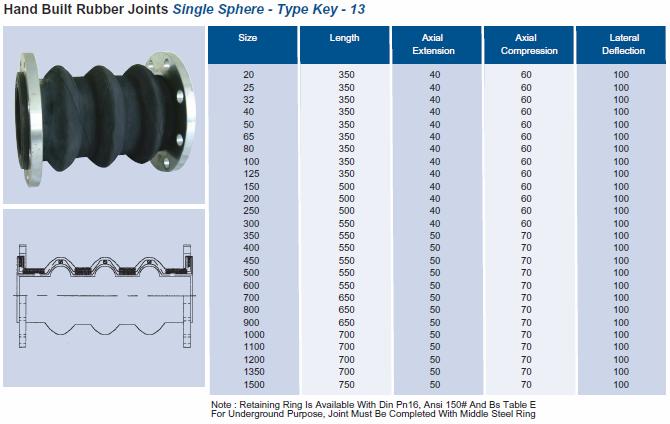

Hand Built Rubber Joints Single Sphere – Type Key – 13

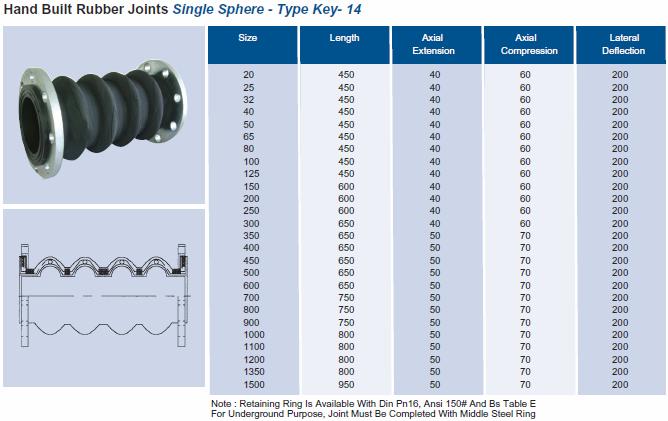

Hand Built Rubber Joints Single Sphere – Type Key- 14

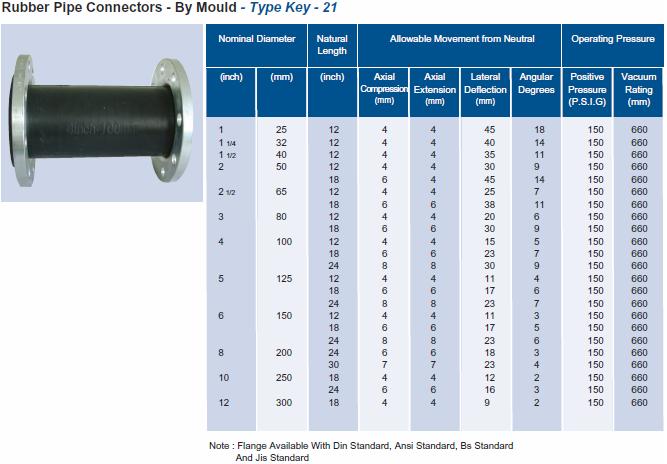

Rubber Pipe Connectors – By Mould – Type Key – 21

Others