Stainless Steel Flexible Hoses

- Keyser Stainless Steel Flexible Hoses

- Installation Methods

- Types & Applications

- Classification of Stainless Steel Flexible Tubes

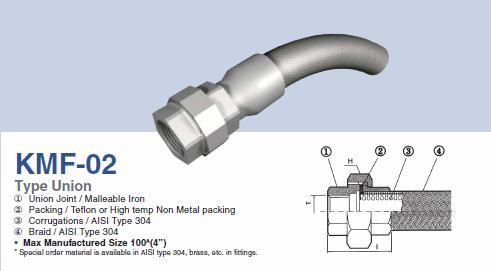

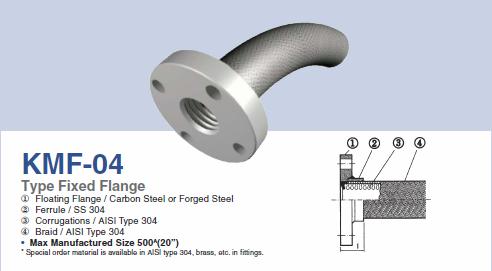

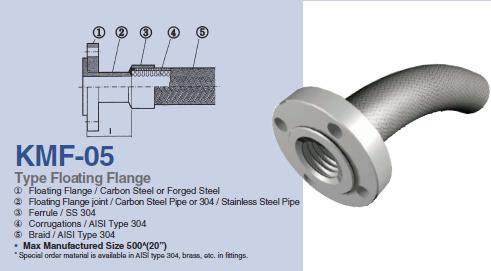

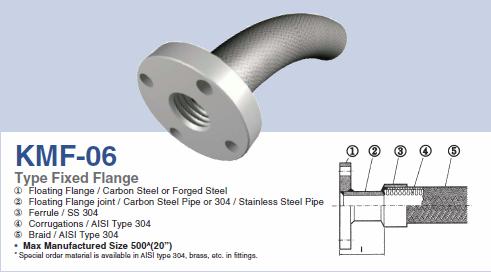

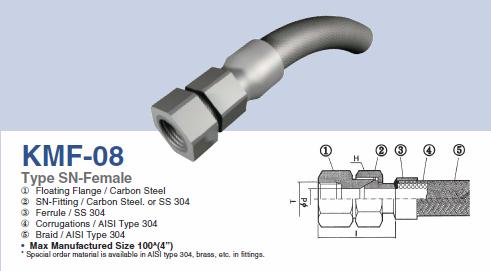

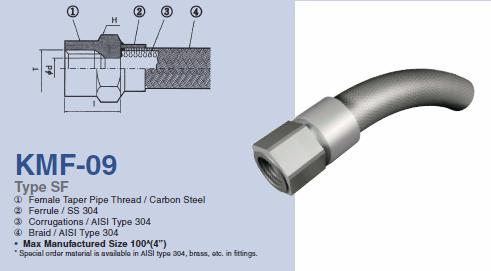

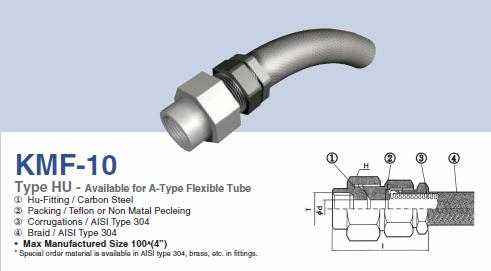

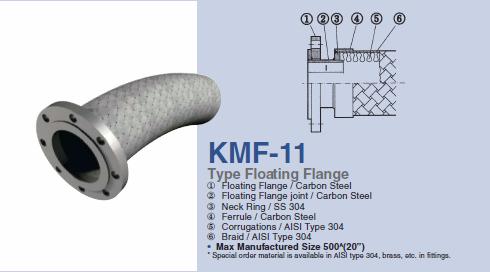

- End Connectors For corrugated Flexible Metal Hose

- Standard Fittings

- Special Flexible Hose Assembly

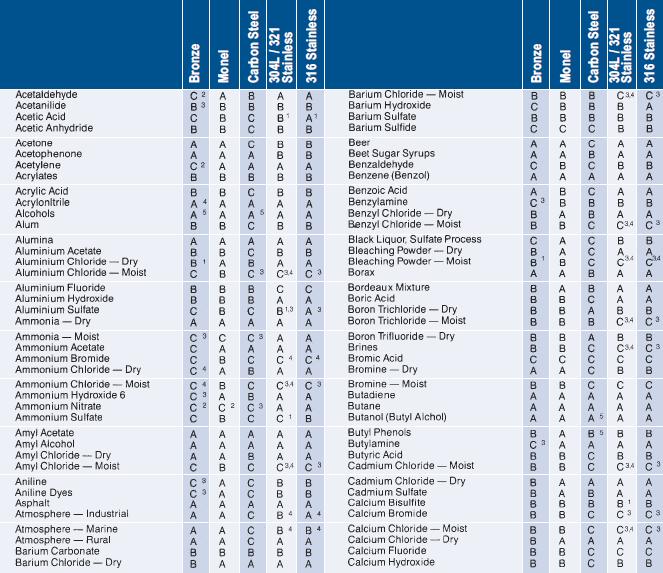

- Corrosion Resistance Reference Table

Keyser Technologies leads the region in advanced flexible hose engineering. Keyser has an unrivaled reputation in the design, manufacture and supply of wide range of metal hoses in the region to suit various industries. The series of stringent tests and quality control ensures a product of the highest possible quality that meets the stringent demands of the industry today. Keyser’s metal hoses are used throughout the region for use in automotive, petrol chemical plants, power generator plants and other industrial applications.

Selection of Metal Hoses

A number of factors affect the selection of the right metal hose for the right application.

1. Pressure

a. Maximum Working Pressure

This is the maximum operating pressure the hose will be subjected to. It is usually at 25% of the Nominal Design Burst Pressure.

b. Maximum Proof Pressure

This is the maximum test pressure the hose will be subjected to. It is usually at 150% of the Maximum Working Pressure with the hose installed straight.

c. Nominal Design Burst Pressure

This is the pressure point where the hose can be expected to rupture. Based on the minimum annealed tensile strength of the braid wire and corrugated hose alloys at 21…C with the hose installed straight.

d. Shock Pressures

When this occur possibly due to fast closing valves, the peak pressure shall not exceed 50% of the Maximum Working Pressure.

e. Pressure Relative to Unbraided Hose

At Maximum Working Pressure, 1 to 2.5% elastic elongation might take place in unbraided hose assembly. The unbraided hose should be unrestrained at one end or installed in a manner to allow free axial expansion due to pressure. This is to avoid squirm from occurring.

f. Pressure Relative to Braided Hose

Elongation occurs when internal pressure is applied to a corrugated metal hose. To avoid this, a wire braid sheath over the hose is applied. The braid has minimal effects on the bending and flexibility.

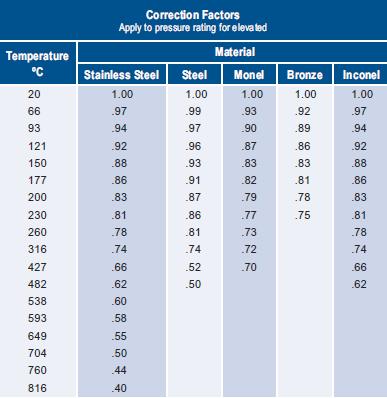

g. Pressure Relative to Temperature

For operating temperatures in excess of 21°C, the tabulated pressures must be decreased in accordance with the table below.

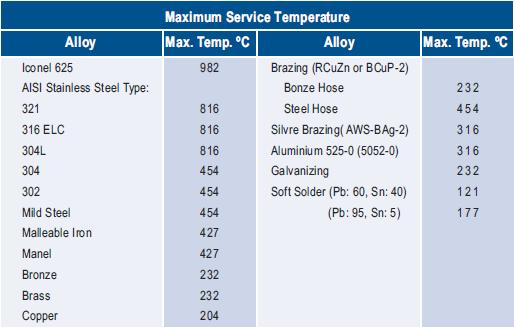

2. Maximum Service Temperatures Of Materials

3. Flow Velocity

a. Use of a fully interlocked flexible metal hose

Where flow velocity exceeds 30.5m/sec (gas) / 15.25m/sec (liquid) in unbraided hose, or in 45.75m/sec (gas) / 22.84m/sec (liquid). In conditions where there are bends, these flow conditions should be reduced by 50% for a 90° bend and 25% for a 45° bend.

b. Use of corrugated metal hose

When the amount of pressure drop through longer lengths of hose is a significant factor, a larger diameter hose may be required. Generally, pressure drop through a corrugated metal hose is approximately three times that in comparable size standard steel pipe.

3. Flow Velocity

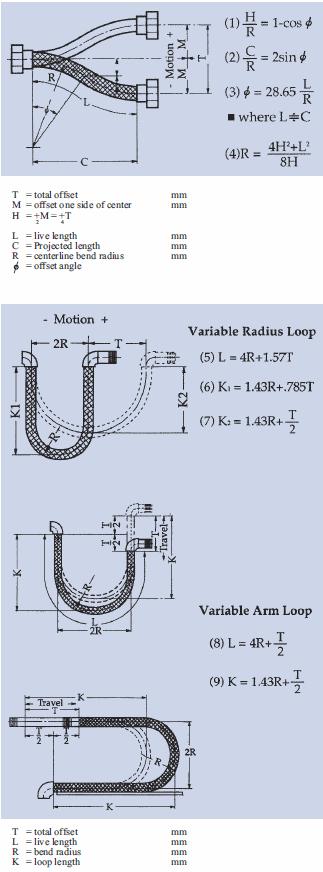

a. Offset Motion

Offset motion is the parallel motion that occurs in a tube with flanges at both ends, while the distance between the flanges remain the same.

b. Radial Motion

When a tube is bent and attached, radial motion is the horizontal or vertical motion at the beginning of the circular arc. Generally called a moving loop, the amount of motion is expressed as the horizontal or vertical distance moved.

c. Axial Motion

Axial motion refers to the dimensional variation of a flexible tube along its longitudinal axis, and displacement is expressed as the amount of extension/contraction.

d. Permanent Bend

Permanent Bends are used in place of ordinary bent pipe to simplify the connection of two piping systems.

e. Random Motion

This is the last mode of motion. A good example will be the garden hose. When it is freely handled, it moves randomly

5. Motion Frequency

A flexible metal hose may be subjected to repeated flexing or bending. Generally, these are separated into basic categories, vibration, intermittent, continuous and static bend.

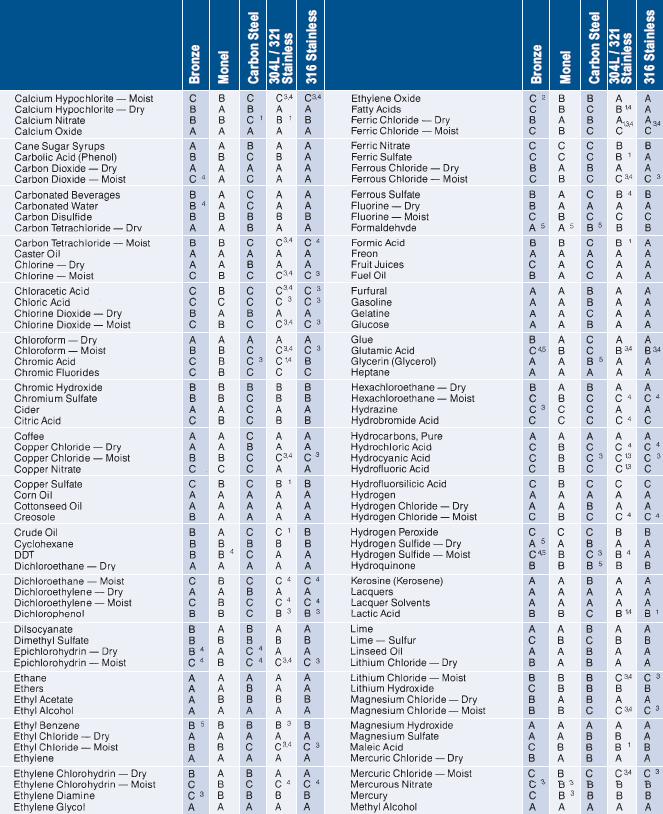

a. Vibration

Vibration is shown as the un-shaded area of the chart in the diagram. When the expected combination of double amplitude and frequency falls into the shaded area, consult our engineers.

b. Intermittent Motion

This refers to the motion that occurs on a regular or irregular cyclic basis due to thermal expansion and contraction.

c. Continuous Motion

This refers to the motion that occurs on a regular cyclic basis normally at a slow cyclic rate and constant travel.

d. Static Bend

This refers to the minimum center line bend radius which a flexible metal hose may be bent for installation.

6. Cycle Life

The cycle life is affected by several factors such as operating pressure, operating temperature, bend radius, materials used etc. The cycle life is also proportional to the sum of the pressure stress range and deflection stress range.

Please note that all these information serves as a general guide only.

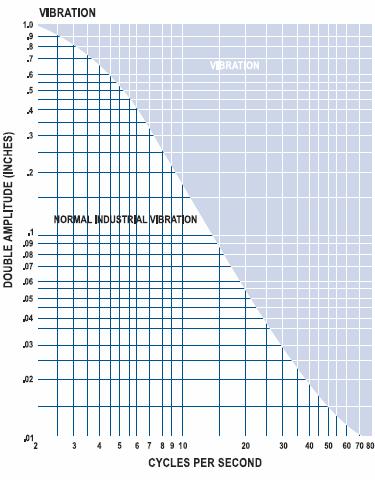

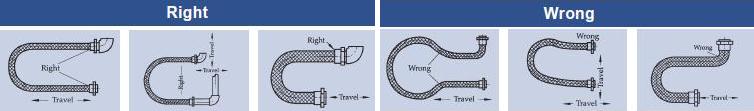

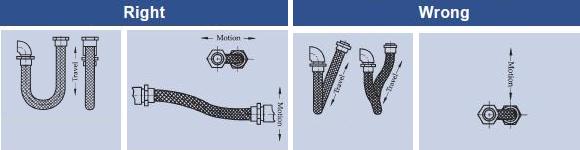

Installation Methods

When installing hoses, there are 2 basic things to take note of.

1. Do Not Torque

a. Use of unions or floating flanges to minimize possible torque damage to flexible tubes.

b. Always install tubes so that flexing takes place in one plane only.

2. Avoid Sharp Bend

a. Due to improper installation, flexible tube can be subjected to recurring sharp bends, which might result in fatigue and premature failure.

Types & Applications

Keyser offers a comprehensive range of flexible hoses. The main advantages of metal hose include high resistance to both high and low temperatures, high strength, high corrosion resistance. They also reduce significantly any vibration or noise. They connects rigid piping which are misaligned to moving parts of machinery and equipment. A variety of choice of metal is available. Such as Bronze, stainless steel, monel and inconel.

Types of Hoses

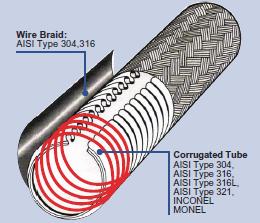

Corrugated Metal Hose

Our complete range is widely used for conveying high pressure and temperature, corrosive and non-corrosive liquids, searching gases and dry materials. We are capable to manufacturing a full range from 1/4 to 16 ID.

Available Materials: Monel, Bronze, Carbon Steel, 321 SS, 316 SS

Interlocking Hose

Interlocked metal hose by helically winding and folding together the edges of specifically pre-formed metal strip. For low-pressure application or where pressure loss is to be held at a minimum, a pre-formed groove inside the interlocked joint is packed with copper/stainless steel wire and asbestos cord.

Bellows

Used primarily used as valve seals and pressure sensing devices, as well as flow channels for all types of media, Keyser Bellows are formed from lap-or butt-welded stainless steel, monel, inconel, hastelloy or any materials that can be weld.

Available Materials: Galvanized Steel, Stainless Steel, Bronze, Aluminum

Interlocked Pressure Hose

High grade treated non-metal packing is simultaneously wound with the metal strip and located in a formed groove. This non-metal high temperature packing in fully-locked construction withstands the pressures to conduct safely non-searching media like water, oils etc. Available in sizes from 1through 4 diameters.

Tar & Asphalt Hose

Used for handling dangerous hottar, asphalt and oil because of their great strength and dependability, Keyser Tar & Asphalt hose incorporates a special helical winding with an non-metal high temperature packing. These are available in a variety of sizes from 3/4 to 4 ID.

Vibra Masters

Keyser Vibra Masters are available in annular corrugated stainless/carbon steel or bronze hoses. Noises, together with pump vibration will be absorbed by these Vibra Masters.

Available Materials: Bronze, Steel, Stainless Steel

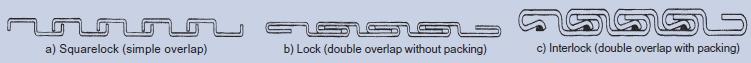

Types of Protections

A flexible metal casing is used to protect the annular corrugated metal hose when it is subjected to external abuse such as dragging etc. Flex-wound interlocked metal hose provides this additional protection. Other coatings such as synthetics are also available on request. There are 2 methods of protection.

Protection Cover

This basic construction type can be categorized by:

a. Double overlap interlock type with packing

b. Double overlap interlock type without packing

c. Simple overlap squarelock type

* Materials used are Monel, Bronze, PVC, Zinc & Stainless Steel

Double Braided

For very high pressure applications, double braided is recommended and for of moderate pressure applications, single braided is recommended. In low pressure applications, braiding is not necessary.

Types of Braid

Ribbon Strip Braids

These can be applied where cracks can be easily formed due to fatigue and high movement frequencies.

a. Exceed 3m in length

b. Used for stationary piping

Flat Wire Braids

a. Used most frequently

b. Used primarily for moving pipes

c. Excels in flexible resistance and pressure resistance

Braided Braids

a. Resistance to pressure significantly increases without sacrificing flex resistance

b. Increase in stretch ability

c. Maximum of 20 ply

d. Used primarily for moving pipes

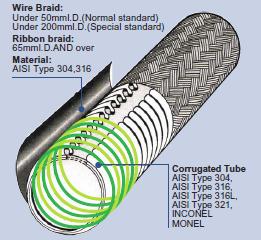

Classification of Stainless Steel Flexible Tubes

Types of Flexible Tubes

S-type (Spiral)

S-Type flexible tubes, made from stainless steel strips, is a helically corrugated tube manufactured by continuously processing the material on a high speed forming machine. It is then annealed in a continuous automatic bright annealing furnace without oxidization to eliminate residual stresses. This is recommended for medium or low pressure application.

A-type (Annular)

A-Type flexible tube, made from stainless steel strip or plate, is an annularly corrugated tube manufactured by continuously processing the material on a high speed forming machine. It is then annealed in continuous automatic bright annealing furnace. Unlike the S-Type, it has annular corrugations, thus it will not twist when subjected to elongation or contraction.

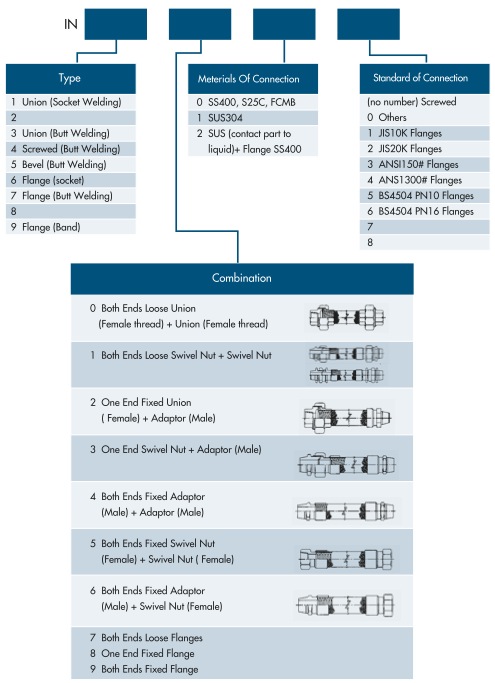

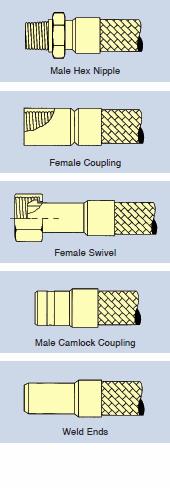

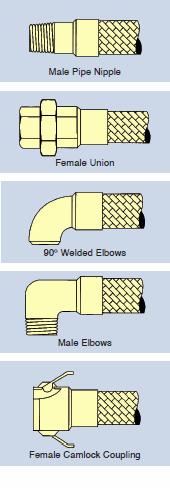

End Connectors For corrugated Flexible Metal Hose

Welding or silver-brazing are methods used to attach the end connectors to corrugated flexible hose.

These flexible hose are suitable for temperatures up to 250° C.

Terminations:

End connectors are available with terminations to current European, American and Japanese standards.

Metals:

End connections are often stocked in carbon steel, copper alloy as well as stainless steel.

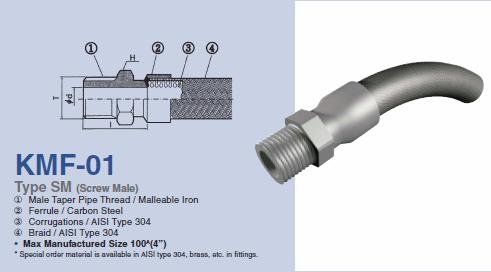

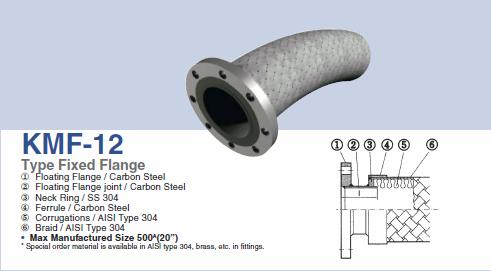

Standard Fittings

Special Flexible Hose Assembly

Jacketed Duples Flexible Tube Assembly

This assembly consists of corrugated stainless steel inner tube and outer one.The jacket area between the inner and outer assemblies contains steam or other heat mediums to heat highly viscous fluid such as heavy oil or asphalt conveyed through inner corrugated tube in order to avoid solidification and clogging.

Flexible Tube Assembly With PTFE Tube

This assembly consists of corrugated stainless steel outer tube and PTFE inner plain tube. PTFE tube is inserted along the inner surface of outer tube to protect it from chemicals and corrosive gasses. As it has excellent properties in not only corrosion resistance but also sanitation, it can be used to convey foodstuff, it provides you with advantages brought from both stainless steel and PTFE. Also available in convoluted fully lined anti-static.

Flexible Tube For Underground Piping

This Flexible tube is designed for the use of underground piping. It has the protective made of synthetic rubber and so on to protect corrosion caused by soil surrounding it.

Others:

- Flexible tubing regulated by LPG Plant Association standard

- Flexible tubing regulated by the Law of High Pressure Control

- Flexible tubing for powder transportation

Corrosion Resistance Reference Table

The table below serves only as a reference guide in the selection of the most suitable host and fitting material. The listed media, unless otherwise stated, is considered to be pure at room temperature. Any change in the room condition will affect the rating. No attempt has been made to account for variation in service conditions since these variables are too complex.

Rating Code:

A – Suitable (normal condition)

B – Limited Service

C – Unsuitable

Note:

1. Susceptible to inter-granular corrosion.

2. May cause explosive reaction.

3. Susceptible to stress corrosion cracking.

4. Susceptible to pitting type corrosion.

5. Discolours.

6. Concentration over 50% and / or temperature over 95°C refer to our Engineering Department.